Case Study

Storage Tank Repair

A client had an issue with localised cracking within a stainless steel storage tank in close proximity to the shell/floor weld. Durham Engineering were tasked with developing potential cost effective solutions to the issue, allowing for a permanent and quick fix due to tight site time constraints.

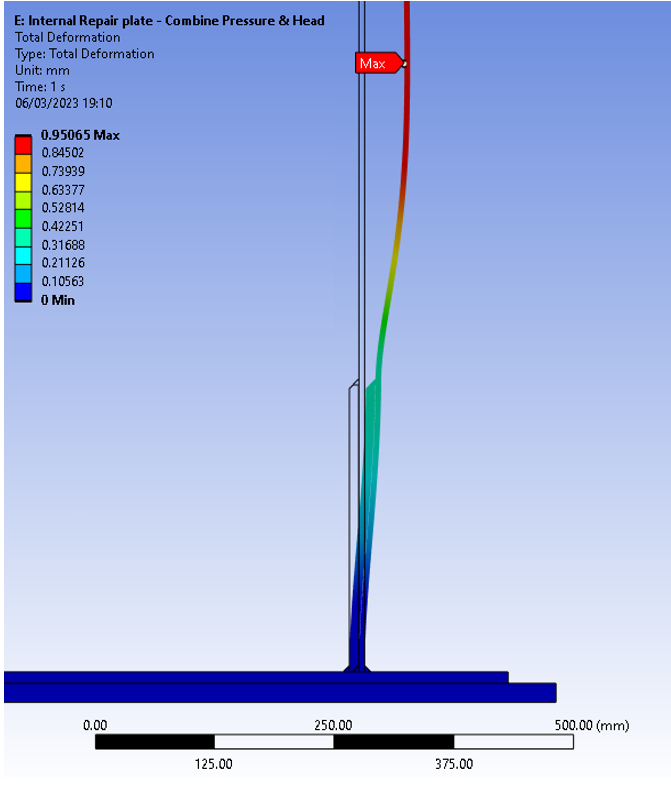

One suggested method of repair was the local over-plating of the inside of the shell. This would effectively stem any leakage form the tank without detrimentally effecting the mechanics of the shell/floor weld joint.

After no example of this repair was provided in any relevant design code, a bespoke approach to the verification of this proposed method was undertaken.

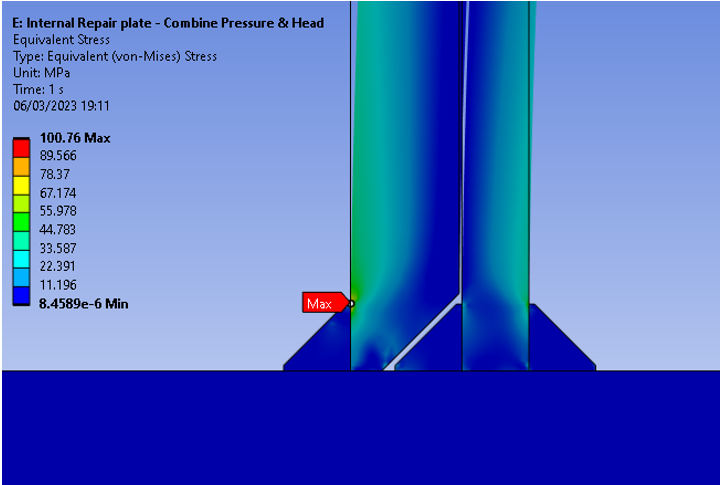

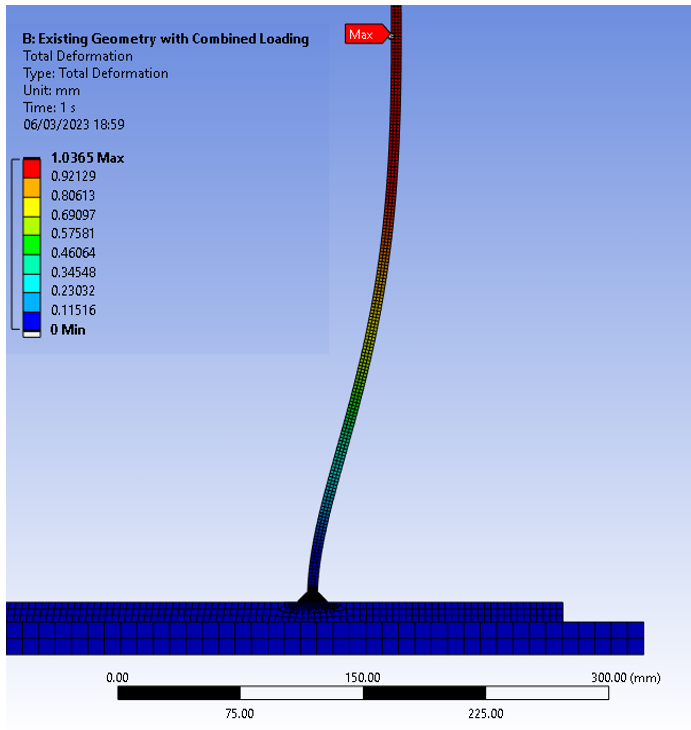

This involved the use of numerical analysis; FEA, to determine the relative displacements and stress levels of the possible repair method with respect to the existing tank weld structure.

From this analysis, the proposed method was found to be a suitable repair scheme.